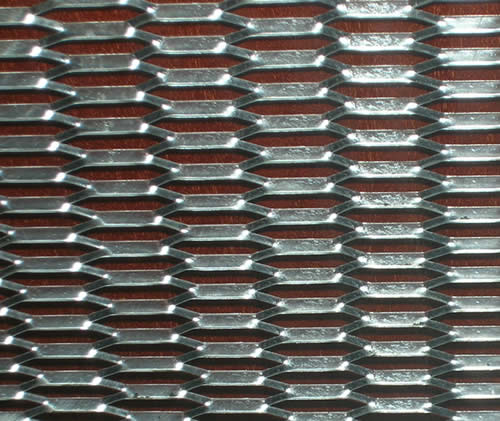

Expanded Metal Grating Floor Panels, 0.5mm to 5mm Sheet Thickness

Expanded Metal Grating (Made of Carbon Steel Mostly) is made of metal sheet expanded in the regular form and then going through a cold rolled reducing mill. In this process the length of the sheet is elongated - usually about 5% - but the width of the sheet remains the same. The sheet is then sent through a leveler to maintain its flatness.

General Information about Expanded Metal Steel Gratings:

Holes: Diamond, Square

Pattern: Standard - raised surface

Feature: Elegant, Press strength, durable, Rustproof, rigid

Common Specification:

Grating Panel (Long way) Size: 4.5 --- 100mm

Short Way Size: 2.5 --- 50mm

Strand thickness: up to 8.0mm

Strand width: MAX to 8.0mm

Benefits of Using Expanded Steel Gratings:

•Expanded metal permits free flow of light, heat, sound and air

•Cost effective alternative to perforated metal. You don't pay for the holes; there is no waste during the expanding process

•Expanded metal grate won't unravel when cut, unlike woven wire

•Available in a variety of mesh configurations including diamond, square, round, hexagonal plus architectural and decorative patterns

•Expanded metal is a formidable barrier when used in security applications

•Easily fabricated, finished, installed and formed

Application: Expanded steel grate panels are mainly applied as platforms and walking stair treads for constructions, vessels, bridges and boilers and also be used as reinforcement for light construction materials and concrete pouring, radiator grills on all types of vehicles and air compressors, safety guards for gear-drive equipment on various kinds of machines.

Expanded Metal Grating Floor Panels Specifications

Plate thickness (mm) |

Hole width(mm) |

Hole length(mm) |

Stem (mm) |

Net width(m) |

Net length(m) |

Weight (kg/m2) |

0.5 |

2.5 |

4.5 |

0.5 |

0.5 |

1 |

1.8 |

0.5 |

10 |

25 |

0.5 |

0.6 |

2 |

0.73 |

0.6 |

10 |

25 |

1 |

2 |

1 |

|

0.8 |

10 |

25 |

1 |

0.6 |

2 |

1.25 |

1 |

10 |

25 |

1.1 |

0.6 |

2 |

1.77 |

1 |

15 |

40 |

1.5 |

2 |

4 |

1.85 |

1.2 |

10 |

25 |

1.1 |

2 |

4 |

2.21 |

1.2 |

15 |

40 |

1.5 |

2 |

4 |

2.3 |

1.5 |

15 |

40 |

1.5 |

1.8 |

4 |

2.77 |

2 |

18 |

50 |

2.1 |

2 |

4 |

3.69 |

2 |

22 |

60 |

2.6 |

2 |

4 |

3.69 |

3 |

40 |

80 |

3.8 |

2 |

4 |

5.00 |

4 |

50 |

100 |

4 |

2 |

2 |

11.15 |

4.5 |

50 |

100 |

5 |

2 |

2.7 |

11.15 |

5 |

50 |

100 |

5 |

1.4 |

2.6 |

12.39 |

Expanded Metal Grate Panels for Platform Construction, 10 mm x 25 mm Spacing

Expanded Carbon Steel Stair Tread, Galvanized

Heavy Loading Grating Panels, 15mm x 40 mm Opening

Expanded Steel Grating is made according to UK, USA, Australia or China Standard. Detail standards, materials standard and hot dipped galvanizing standard as follows.

| Steel Grating Standard | Steel Material Standard | Hot Dip Zinc Coating Standard |

| China Standard: YB/T4001—1998 |

China Standard: |

China Standard: |

| USA Standard: ANSI/NAAMM(MBG531—88) |

USA Standard: ASTM(A36) |

USA Standard: ASTM(A1 23) |

| UK Standard: BS4592—1987 | UK Standard: BS4360(43A) | UK Standard: BS729 |

| Australia Standard: ASl 657—1 992 | Australia Standard: AS3679 | Australia Standard: ASl650 |

Expanded metal grating is the most practical and economical way to assure strength, safety, and a non-skid surface. Expanded metal grating is ideal for use on plant runways, working platforms, and catwalks, as it is easily cut into irregular shapes and can be installed quickly by welding or bolting.

Classification of Expanded Metal Steel Grating according to opening:

Variety: small, medium and heavy expanded metal. Opening in the shape of diamond, hexagonal or special shape.

Our most popular steel gratings:

•Heavy duty hot dip galvanized steel gratings (hot dip galvanizing after fabrication)

Size of the grating – 925mm × 1000mm

Square Cross Bar – 10 mm × 10mm

Bearing Plate – 120mm × 6mm thickness

Opening (pitch size) – 45mm × 45mm

2 sides has C Channels, size 100mm × 50mm × 5mm welded to the main bearing bars.

•#316 stainless steel grating with 1-1/2" × 1/8" bearing bars at 1-3/16" o.c. (19 - SGSS-4) 36" wide × 24' long.

•#316 stainless steel grating with 1" × 3/16" bearing bars at 1-3/16" o.c. (19 - SGSS-4) 36" wide × 24' long.

•Fabricated rectangular grating panels in mild steel material, width 500mm-1300mm and length 700mm/1000mm. Load bar size 65 × 10 mm, Load bar pitch 35 mm, cross bar pitch 100 mm, load bar type serrated, 8 mm twisted square cross bar/ round rod cross bar, hot dip galvanized.

•Press-locked galvanized steel grating, the bar is 30mm × 3mm thick, and square type 35mm × 35mm

•Steel grating mesh 34 × 38 BP 30 × 3 dimension 1000 × 5800 galvanized or self-colored

•Walking stairs dimension 280 × 800 mesh 34 × 38 BP 30 × 3

•Gratings for operating floors:

Material: ASTM A36

Mesh Pitch 32 × 32 mm

Load bearing bar size: 40 × 5 mm

Transverse bar size: DIA 5mm (support bar)

Binding bar size: 40 × 5 mm

Protection: all surfaces to be made free from rust & scales by chemical cleaning

Grating size 1500 ×1000 mm × 40

Grating size 1800 ×1000 mm × 40

Carbon steel grating with anti-slippery (anti-skid) surface, plate dimension (high × thick) 1-1/4 × 3/16 inch, grating dimension (width × long) 36 × 120 inch, separation inter plate 1-3/16 inch, separation inter bar 4 in, bar diameter 1/4 inch, coating galvanized- 620g/m2.